Capabilities

Design & Engineering

Uni-Grip supplies on-site engineering consultation to our customers where desired and appropriate. Many new and collaborative designs have come from this synergy—reducing installation time, simplifying parts structures and improving results. All we do helps our customers as we partner with them to find or develop the product for their specific need.

We look forward to working with you. Contact us for more information.

- We design and fabricate 100% of our extrusion tooling, reducing lead times

- Our extensive experience makes the difference in satisfying your needs

- Solidworks 3D CAD software for in-house die design

- BobCAD CAM software for in-house die manufacturing

- Uni-Grip works with many file formats, and works with your files whenever possible

- We create CAD models, part prints, and prototypes with very short lead times

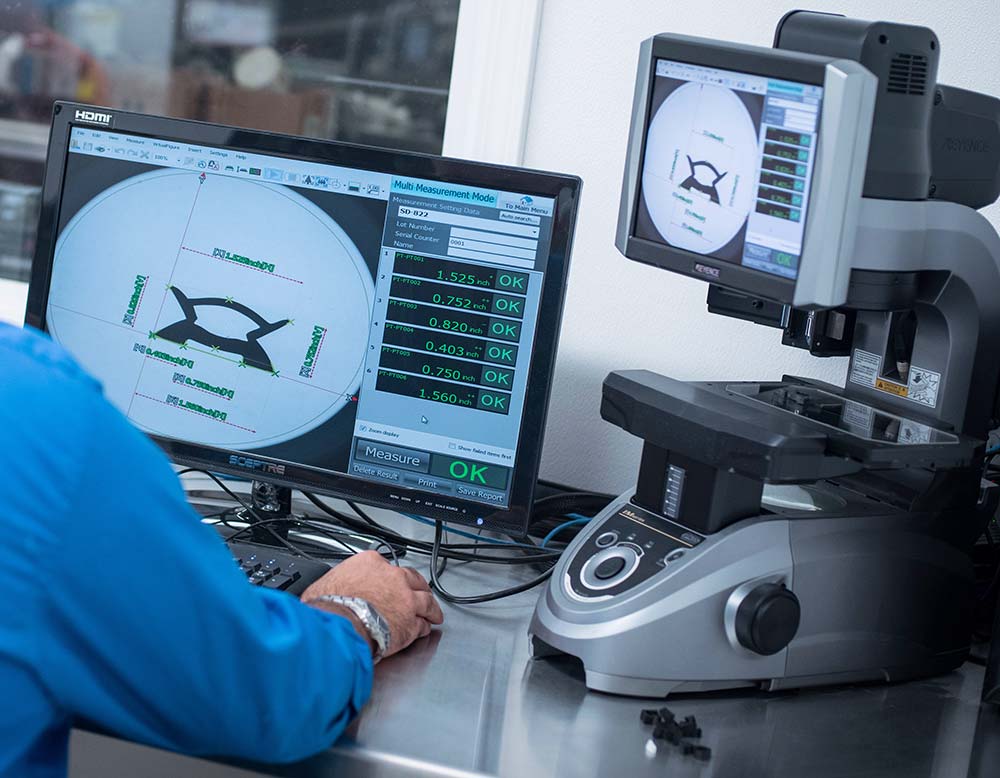

- Our APQP process ensures your needs are met with quality, reproducibility, and reliability

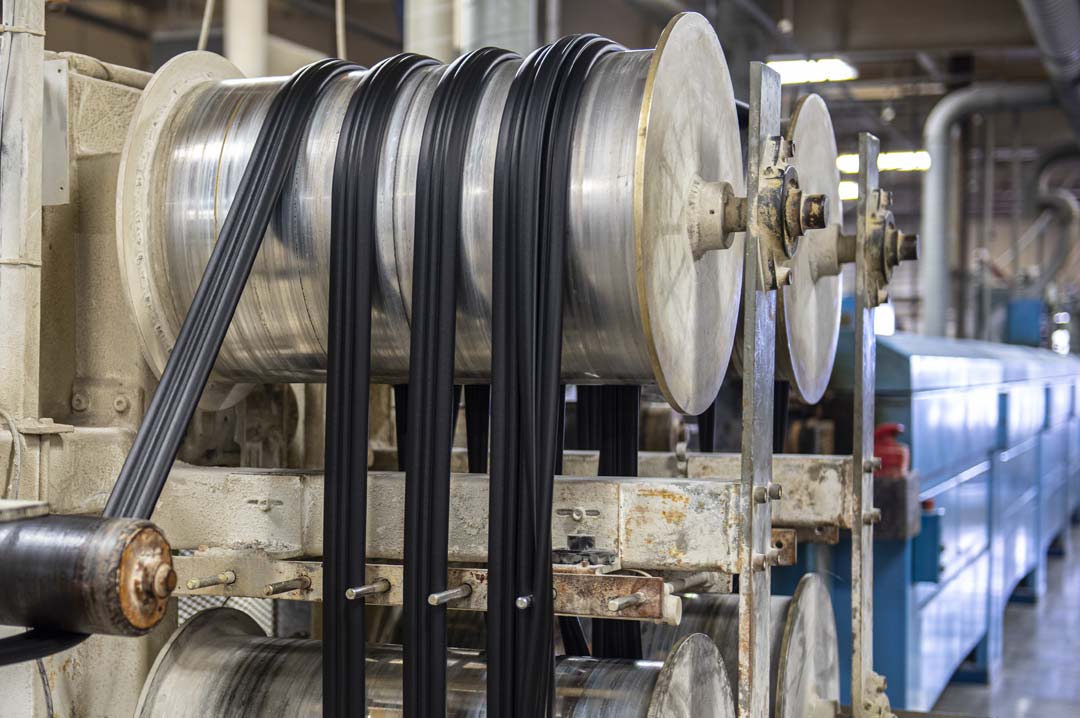

Extrusion

Rubber

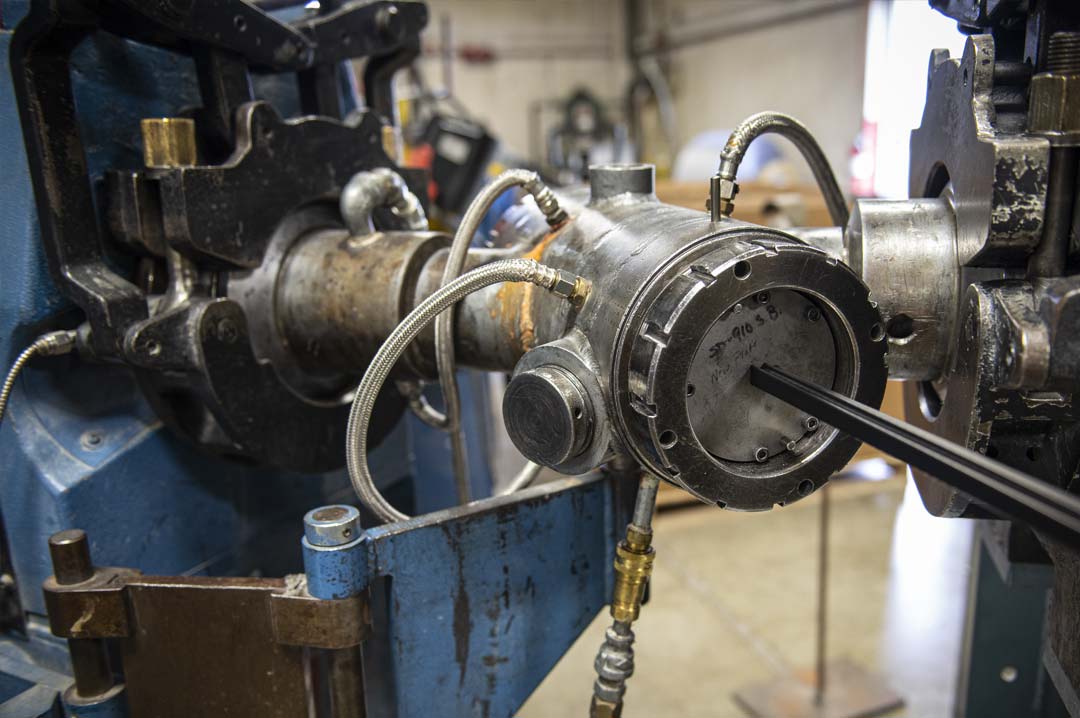

- Lines for 2.5 inch and 3.5 inch screw sizes, as well as co-extrusion

- Insertion of steel clips, encapsulation of U-channel wire or aluminum

Plastic

- Lines for 1.5 inch and 3.5 inch screw sizes

- Encapsulation of U-channel steel or aluminum

Co-Extrusion

Uni-Grip joins dense and sponge rubber into a single seal. These dual durometer seals provide capabilities beyond any single material. Dense rubbers provide superior durability while sponge rubbers provide superior sealing capability.

Tooling

Uni-Grip produces all its own extrusion and progressive dies, allowing us a high degree of quality control and fast turnaround times. Our engineers often take your idea from sketch to finished prototype in a matter of days.

Value-Added

Uni-Grip provides time and money-saving conveniences to our customers with an array of value added services. Our engineering team has many years of proven experience in designing much of our equipment, ensuring the highest quality throughout the entire manufacturing process, no matter what the need.

Value added processes combined with top quality products offer a complete solution for our customers. This saves both time and money.

In addition to our metal clips and tape applications, Uni-Grip provides many post-extrusion processes for your convenience. We cut parts to length, create precision corner joins, drill vent and drain holes, and add lubricants for ease of insertion. Your seal will immediately integrate into your workflow upon receipt. Some of our value added services are:

- Vulcanizing, both straight splicing and corner joining

- Die cutting and press punching

- Cut to length

- Insert spring steel or aluminum

- Slip coat or powder equivalent coatings for installation ease

- Drill vent or drain holes

- Insert bulb reinforcements

- Apply heat activated (HAT)/pressure sensitive (PSA) tape or hook-and-loop (PSA) fastener

Materials

Rubber (Elastomer) Compounds

Rubber's elasticity, compressability, and durability are key to many sealing and weather stripping applications. Our most frequently requested rubber materials are summarized below.

- EPDM (Ethylene-Propyline-Diene-Monomer) compounds are very widely used in general-purpose applications, especially for outdoor use.

- Silicone (Polysiloxane) functions well across a wide temperature range, is color stable, and remains flexible. This material delivers where many others cannot.

- Nitrile (Acrylonitrile-butadiene) can provide very good chemical resistance and can be customized for outdoor uses.

For more information about rubber compounds, follow these links: General Rubber | Specialty Rubber

Plastic Compounds

Plastic materials are also commonly used in edge trim applications and provide different characteristics from rubber such as cost and appearance. Our most requested plastic materials are summarized below.

- TPE (Thermoplastic Elastomers) combine properties of both rubber and plastic and is a very versatile material. Durometer values range from 0 (Shore A) to 65 (Shore D).

- PVC (Polyvinyl chloride) is often used in outdoor applications, providing both durability and flexibility. Durometer values range from 40 (Shore A) to 60 (Shore D).

Metal Carriers

Steel or wire (aluminum or steel) carriers are available to provide extra support when rubber alone cannot complete the task. We perform progressive die stamping in-house to ensure high quality for our finished products. These dies are also created in-house, providing for tight tolerances. Our experience is unsurpassed as we have been stamping steel with these types of dies for over 50 years.

High Strength Low Alloy spring steel is a desired feature of many of our profiles, reducing both weight and cost when compared to medium strength steels. This distinctive steel and shape of our seals also provides stronger pull-off force and flexibility than other carriers.

Corrosion inhibitor is applied after stamping to help ensure long product life.

Widths typically range from 0.750" to 2.000", depending on the material. Contact us for more information.

| Metal Carrier Guide | Typical widths |

|---|---|

| Steel | 0.750" to 1.525" |

| 1008-1010 steel (0.018" thick) | 0.750" to 1.525" |

| High Strength Low Alloy | 0.750" to 1.525" |

| Aluminum | 0.750" |

| Wire carrier | 0.750" to 2.000" |

Adhesives

Our adhesives provide durable bonds wherever they are required. These are often used where wire or steel carriers are not possible.

3M™ Heat Activated (HAT) and Pressure Sensitive (PSA) tapes are both used widely by our customers, with proven success. Some customers request hook-and-loop fasteners instead of tape, providing for simple detachment and reattachment.

Widths typically range from 1/4" to 1", please contact us with your needs.

| Adhesive Guide | Typical widths |

|---|---|

| PSA Acrylic Paper Tape | 3/8" to 3/4" |

| 3M™ HA Tape Ex: ST1200, WT4112, 5933 | 1/4" to 1" |

| 3M™ PSA Acrylic Foam Tape | 1/4" |

| PSA Hook-and-Loop Fastener | 1/2" |