About Us

Welcome!

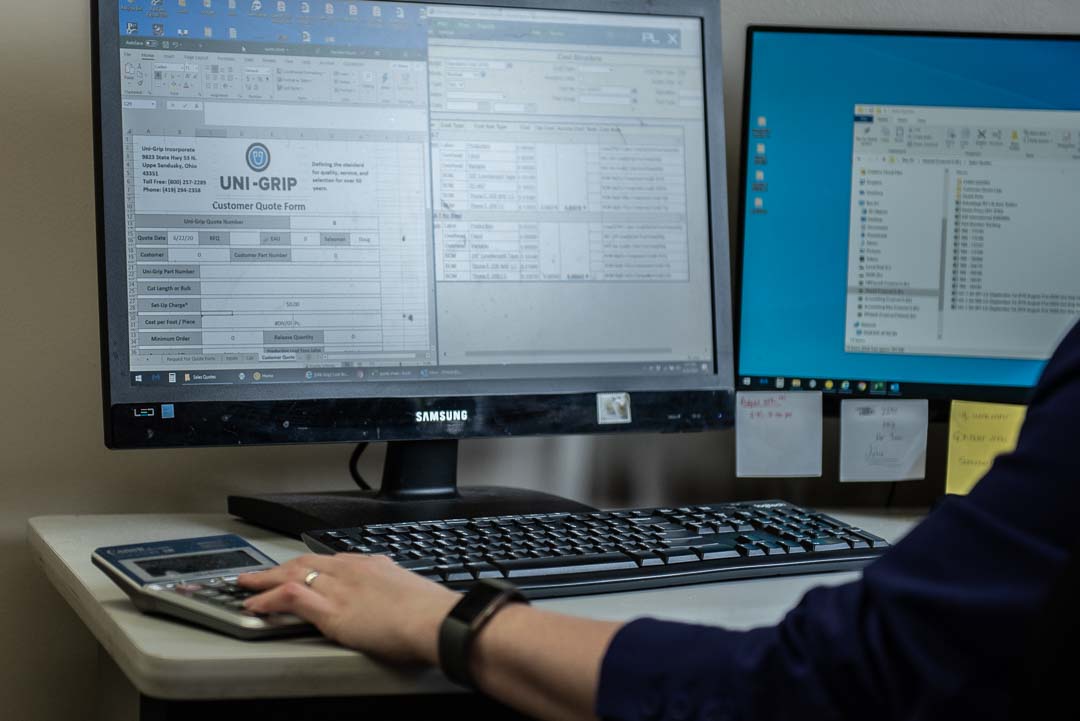

Uni-Grip manufactures extruded rubber and plastic seals and edge trims to many industrial clients both large and small. Our profiles protect diverse products such as heavy equipment, recreational vehicles and garage doors from air and moisture infiltration. We produce a wide variety of stock profiles, and we have design and tooling capability in-house, so we provide rapid turnaround on new products. Our in-house sales staff has 100+ years of collective product knowledge—if you have a question about our products, they will have an answer.

We proudly produce all of our own profiles domestically—however we provide product world-wide. We also provide value-added procedures, such as cut-length parts and pre-assembly to make our customer’s lives easier.

Uni-Grip is committed to excellent quality and on-time delivery. Adherence to ISO 9001:2015 and continuous improvement is in our DNA. We employ manual and automated inspection to make sure it’s right before it goes in the box.

Since 1963, we have been located in rural Ohio by choice. We're still here, and intend to stay here. We’re a team, and we are as committed to our people as we are to producing excellent products.

My family has owned Uni-Grip since 1973, and I am delighted to be a second-generation owner. We honor our past, but are building the future. We look forward to serving you as a valued customer.

Deb King, CEO

Team

Andrew Mathias

President

Ext. 133

Deb King

CEO and Owner

Mike King

IT Director

Chuck Billeg

Director of Plant Operation

Ext. 117

Kip Alspach

Director of Process Engineering and Tooling

Ext. 135

Sam Newman

Operations & Planning Mgr.

Ext. 118

Creston Kinley

Operations & Purchasing Mgr.

Ext. 114

Raychelle Hill

Shipping Manager

Ext. 138

Allyssa Kessler

Customer Service Clerk

Ext. 113

Wendy McQuistion

Customer Service Clerk

Ext. 137

April Dible

Accts. Receivable Coordinator

Ext. 100

Anali Camacho

Customer Service Clerk

Ext. 124

Why Uni-Grip?

Our leadership team is driven by Key Performance Indicators to focus our team on Quality, Cost, Delivery and Service to insure that our customers are fully satisfied.

Quality

Uni-Grip is fundamentally committed to continuous improvement. 100% product quality is our goal. ISO 9001:2015 standards fortify and guide everything we do. We hold to some of the tightest tolerances in the rubber and plastic profile extrusion industry. Uni-Grip employs both manual (visual, micrometers, and densimeters) and automated inspection (Keyence and Starrett) technology to ensure products conform prior to shipment. We make sure it's right before it goes in the box.

Cost

Uni-Grip launches new products and programs through a series of checklists that guide our cross-functional team to eliminate waste. It is the objective of APQP at Uni-Grip to maximize engineered quality while minimizing excessive labor, scrap, and inventory. We use continuous and periodic dimensional measurements to link our dimensional measurements to our specifications to insure repeatability and continuous fit / function. Continuous Improvement is critical to our leaders, our management, our ISO Quality System, and our entire team.

Delivery

We expect to have 100% on-time delivery—it's our commitment to you. Our team works hard to utilize our advanced ERP software to insure raw materials are supplied and finished goods are produced to meet demand. The internal systems at Uni-Grip ensure our Quality, Production, Sales, and Customer Service teams are synchronized to meet and exceed delivery expectations of the customer.

Service

Our dedicated and skilled teams are committed to superior Quality, competitive Costs, and on-time Delivery. Customer service starts before the sale, and continues during and after delivery of a purchase. We work hard to win new projects with competitive costs for tooling and extruded product. Once the sale has been made, service continues with active communications, follow-up, and responsiveness. When issues occur and expeditious action is necessary, Uni-Grip calls upon multiple team members that work to solve problems through 5Y and 8D processes. Concurrently, other equally empowered leaders work to get product qualified and shipped to the customer. Customers enjoy our willingness to share our many skills like tool design, production quality systems, quality analysis toolbox, and in-depth raw material knowledge. Highly skilled and experienced engineers apply scientific extrusion processing methodology to insure that products will run accurately and with sustained repeatability.

Credentials

Uni-Grip Inc. has been certified to the ISO standards since 2005. Our current ISO 9001:2015 addresses various aspects of quality management. The standards provide guidance and tools for our company to ensure that our products and services consistently meet customer's requirements, and that quality is consistently improved. Uni-Grip applies ISO 9001:2015 quality management principles including a strong customer focus, the motivation and implication of top management, the process approach and continual improvement. Using ISO 9001:2015 helps ensure that customers get consistent, good quality products and services, which in turn brings many business benefits.

Uni-Grip applies the ISO management system standards on the principle of continual improvement. Our organization assesses its current situation, fixes objectives and develops policy, implements actions to meet these objectives and then measures the results. With this information the effectiveness of the policy, and the actions taken to achieve it, can be continually reviewed and improved.

Uni-Grip is a member of the Association for Rubber Products Manufacturers.

Uni-Grip is also certified as a Women-Owned Business Enterprise (WBE) by the State of Ohio.